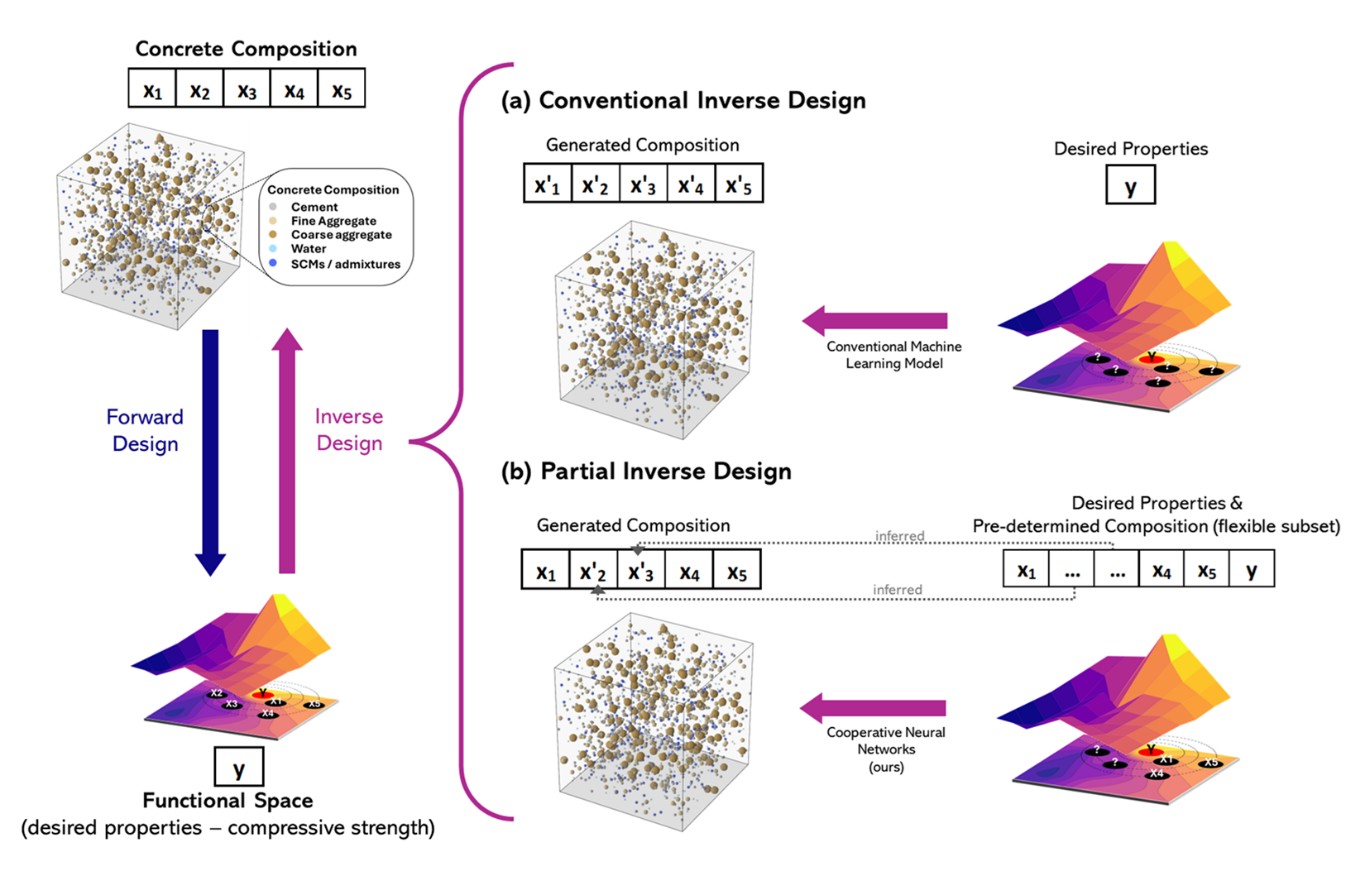

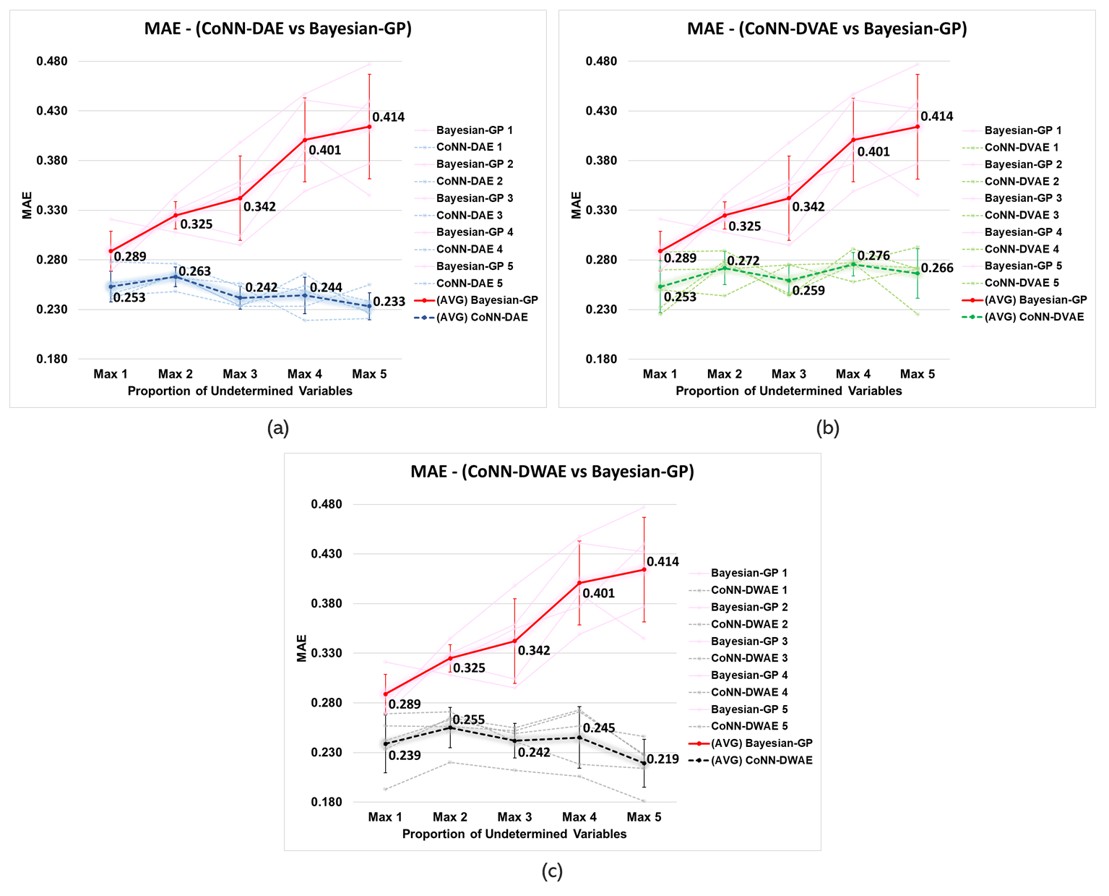

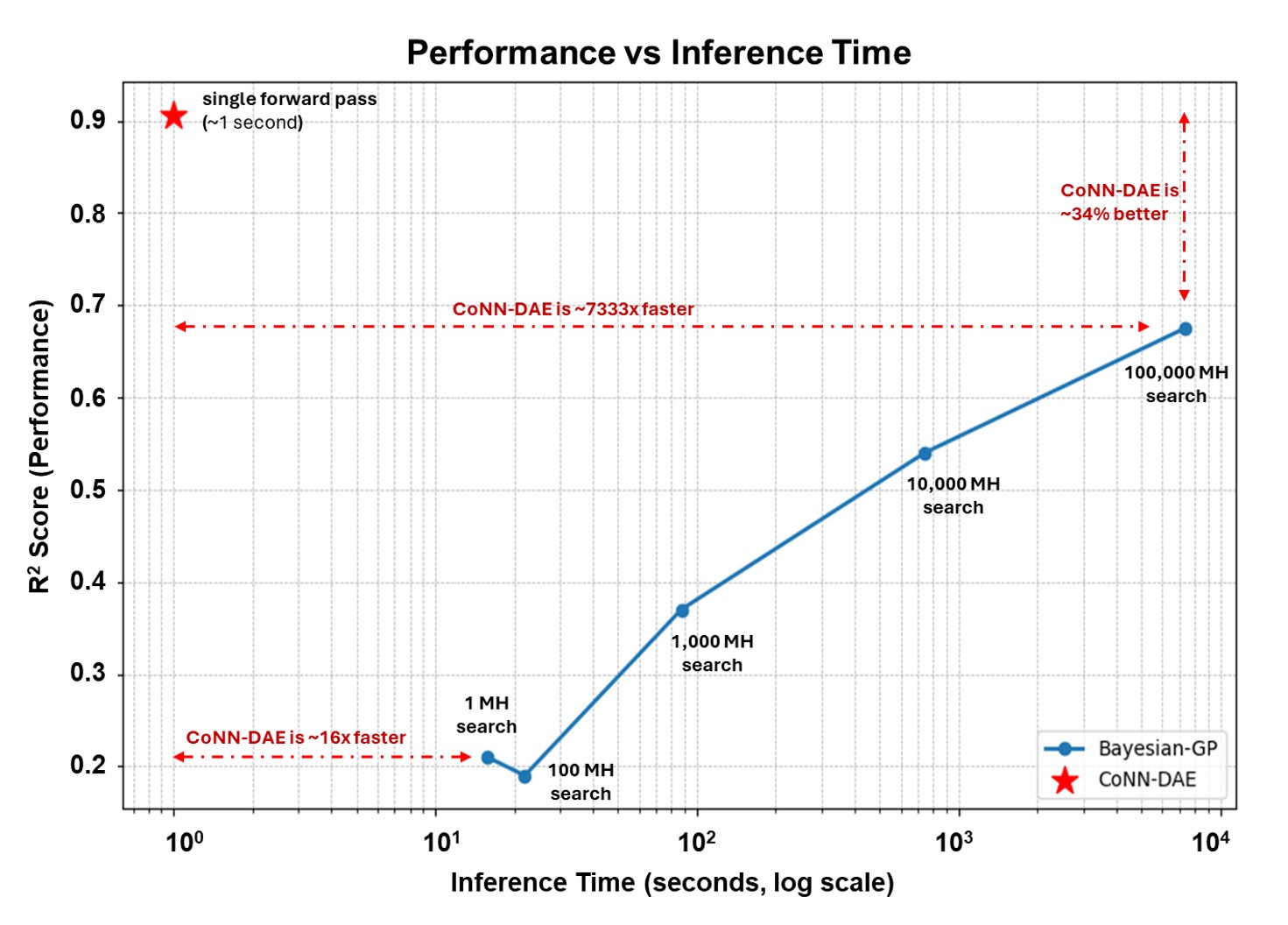

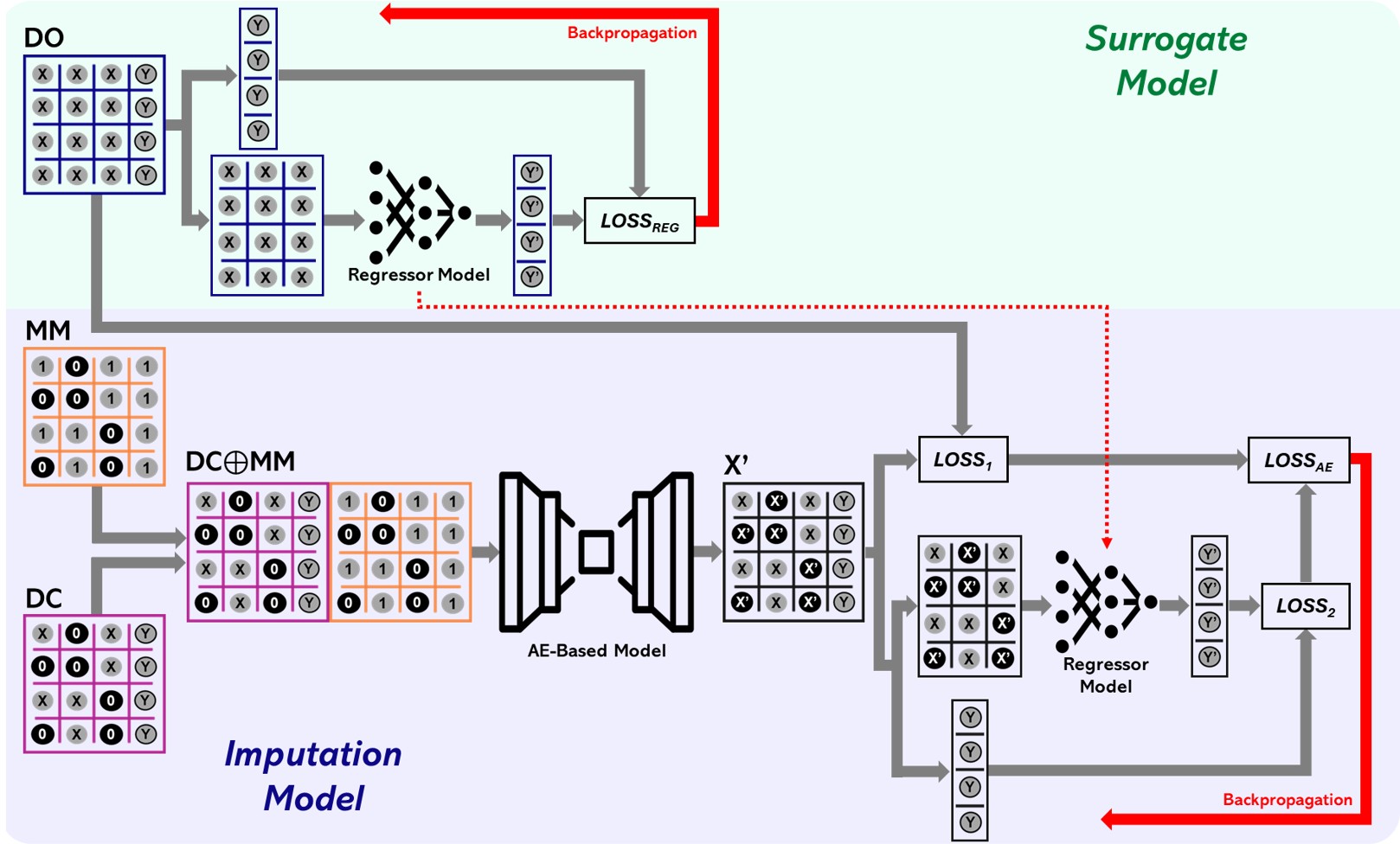

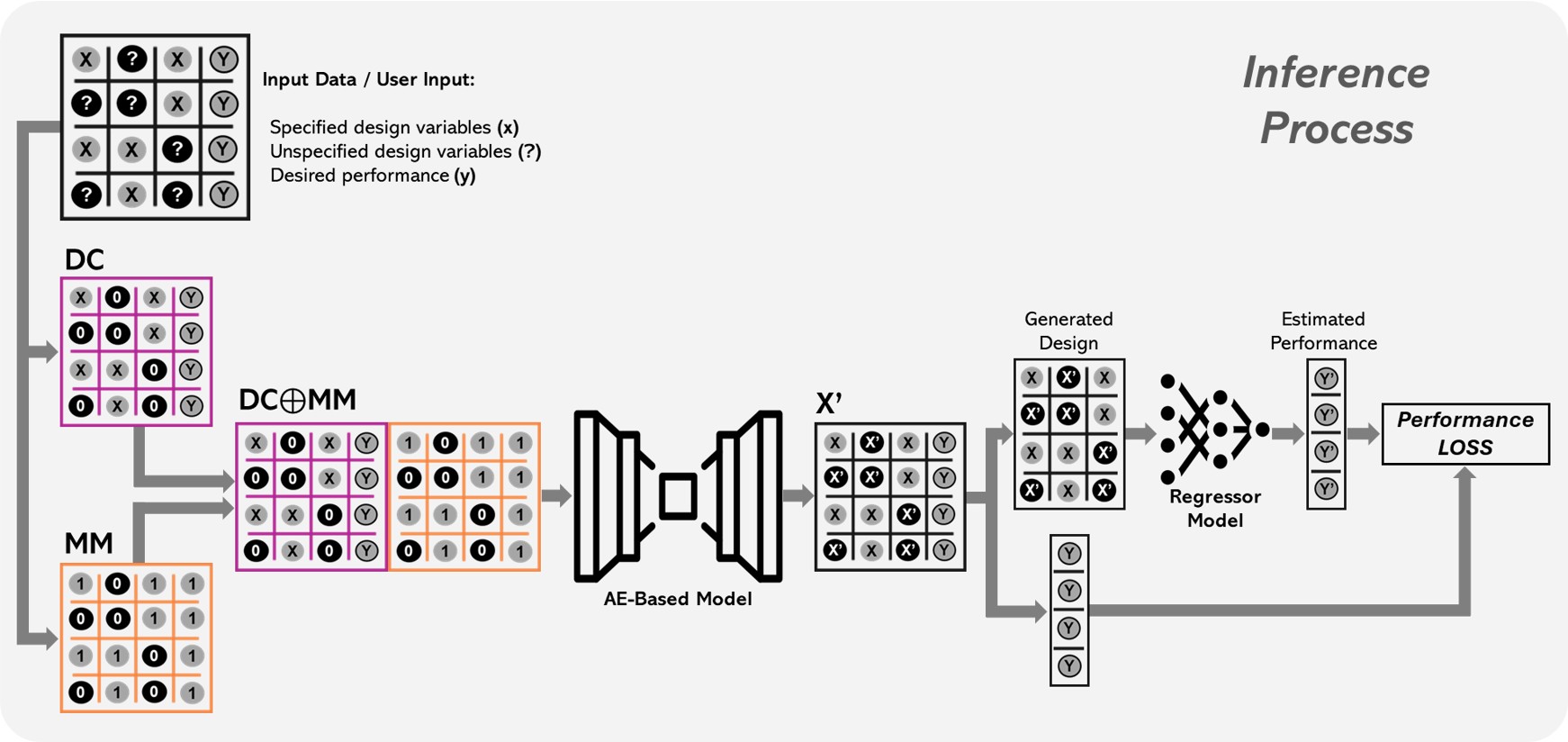

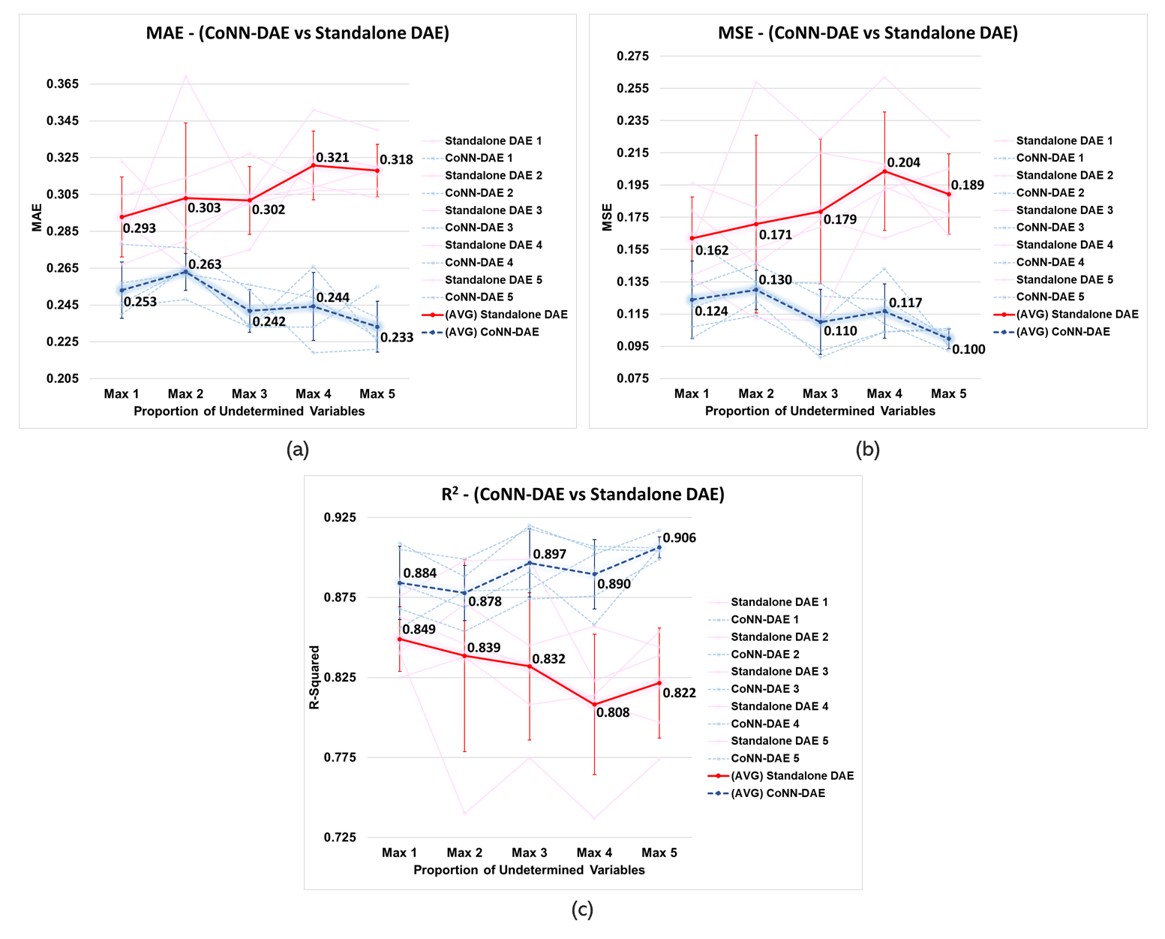

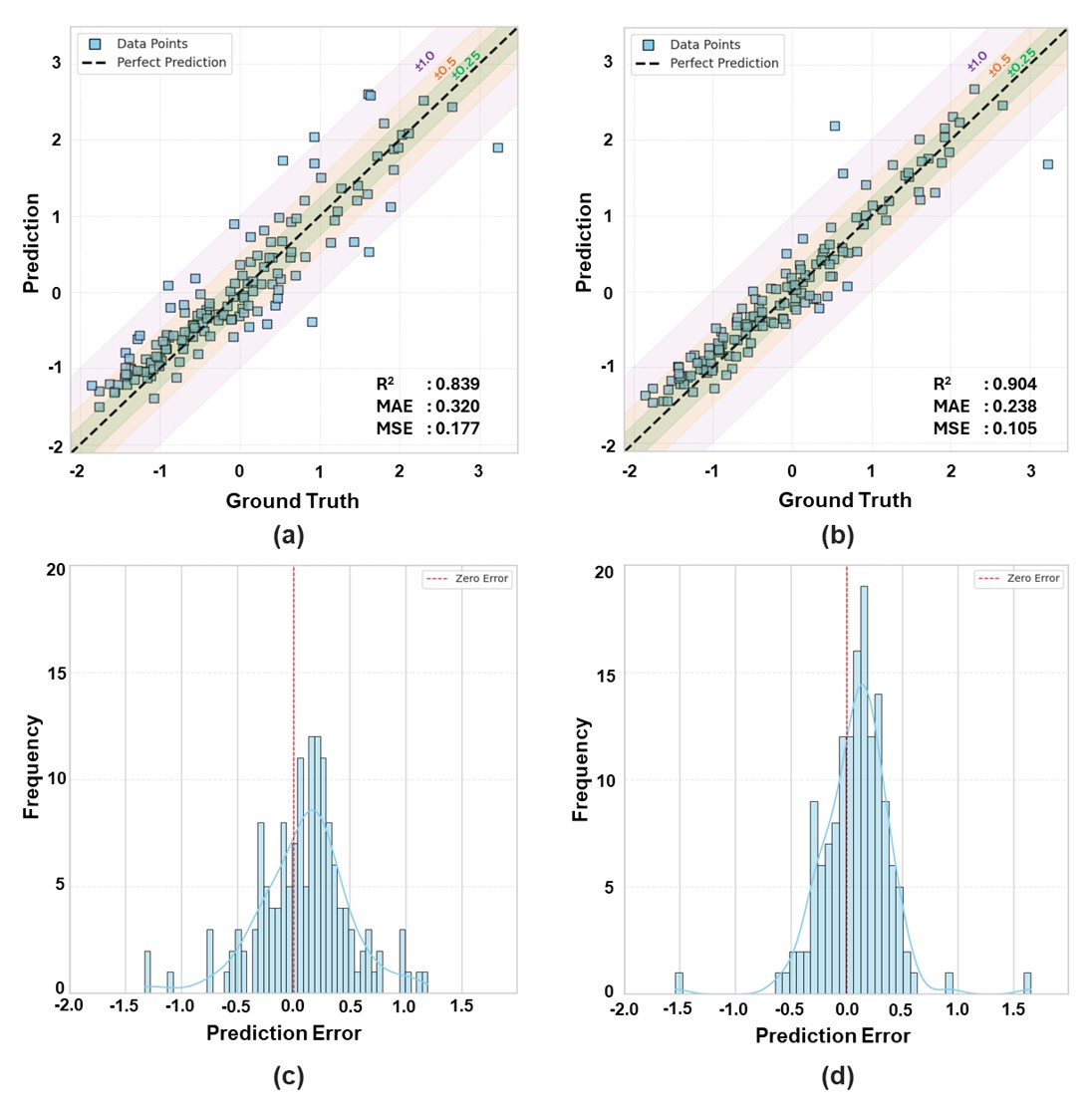

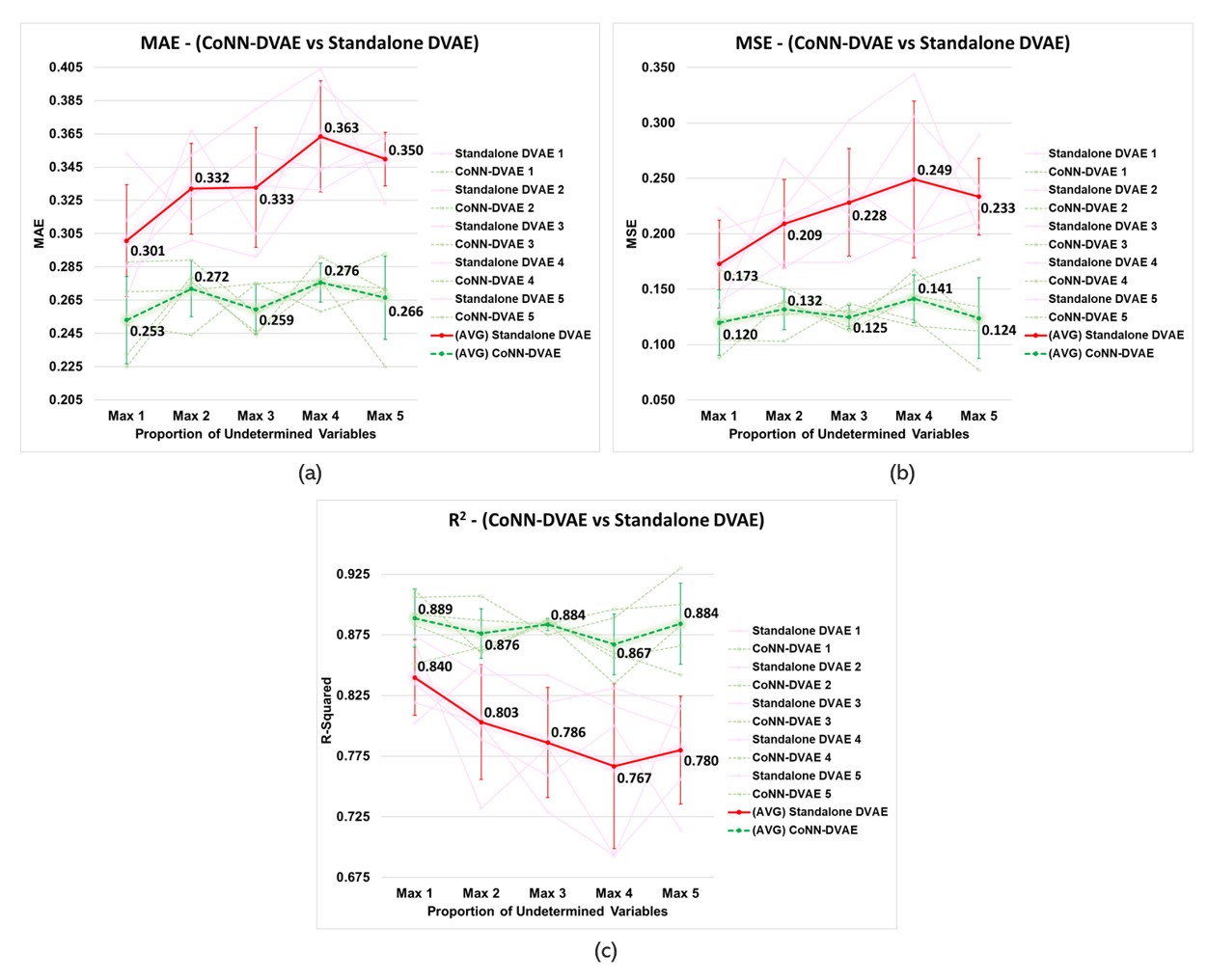

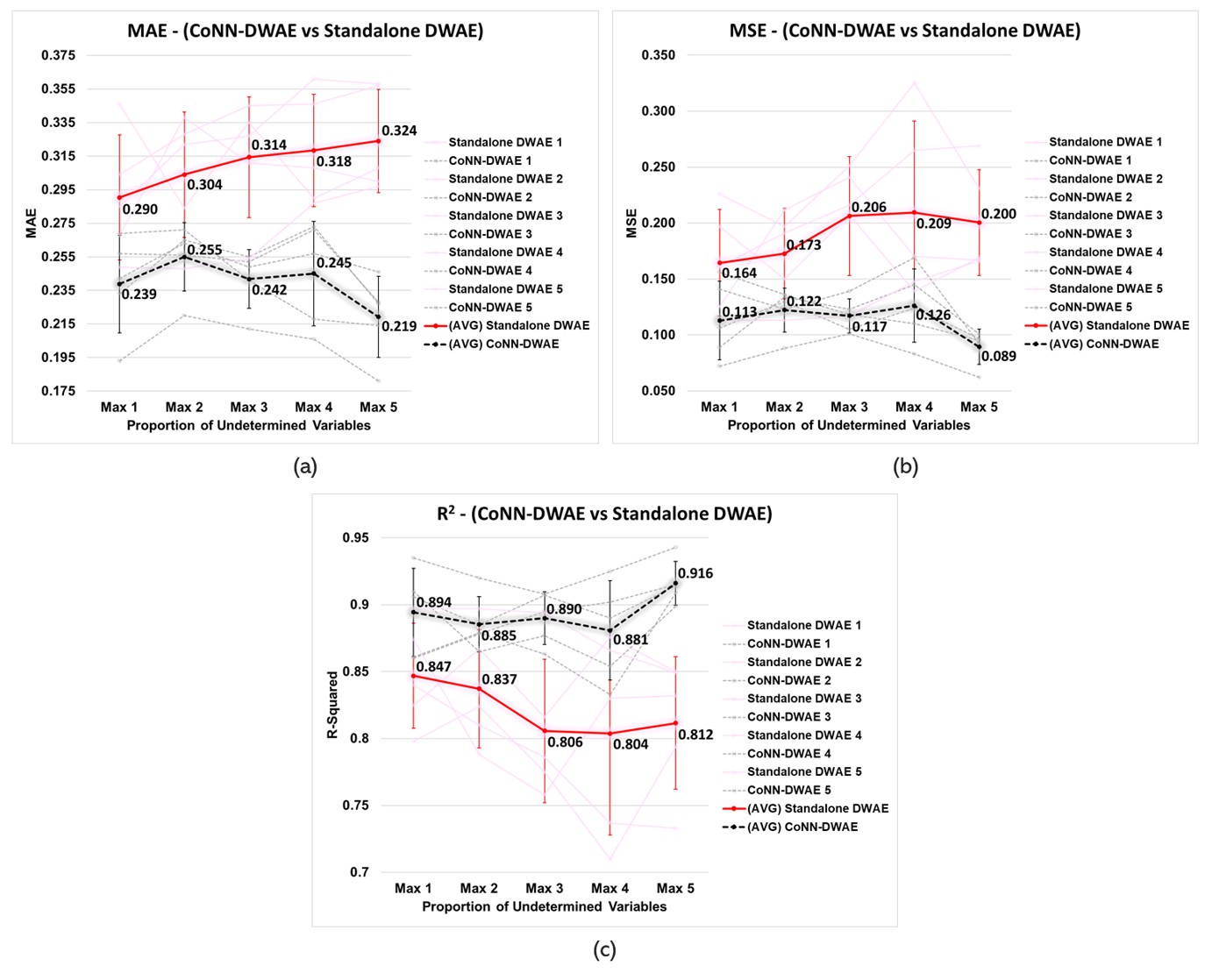

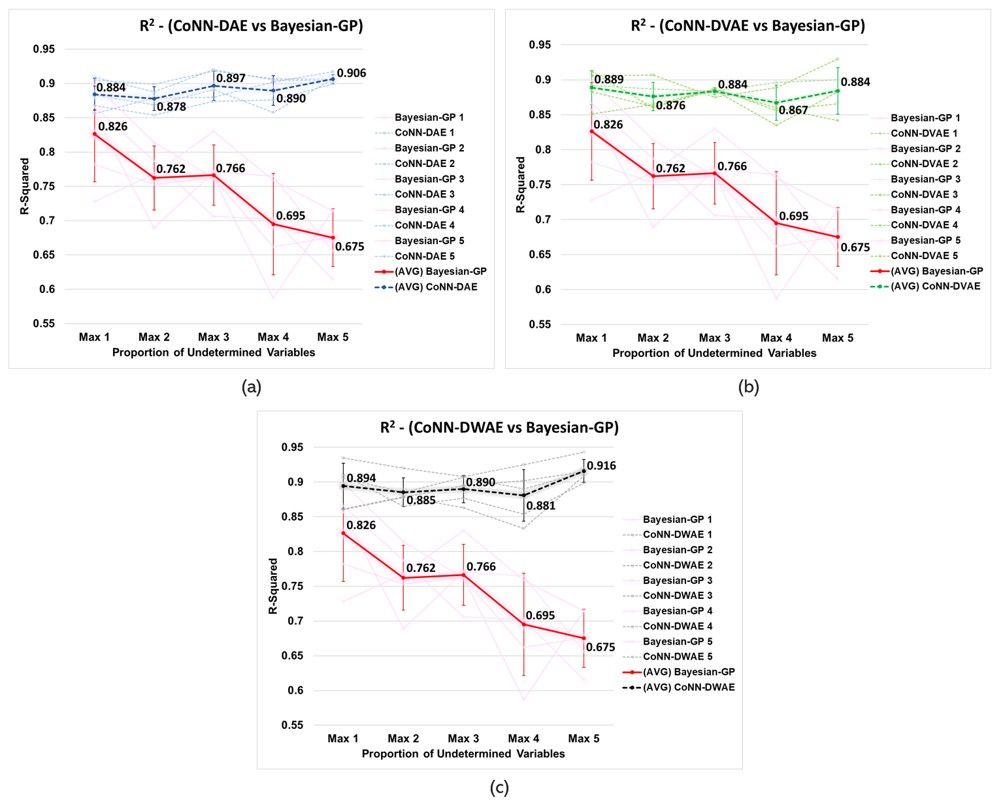

High-performance concrete requires complex mix design decisions involving interdependent variables and practical constraints. While data-driven methods have improved predictive modeling for forward design in concrete engineering, inverse design remains limited, especially when some variables are fixed and only the remaining ones must be inferred. This study proposes a cooperative neural network framework for the partial inverse design of high-performance concrete. The framework integrates an imputation model with a surrogate strength predictor and learns through cooperative training. Once trained, it generates valid and performance-consistent mix designs in a single forward pass without retraining for different constraint scenarios. Compared with baseline models, including autoencoder models and Bayesian inference with Gaussian process surrogates, the proposed method achieves R-squared values of 0.87 to 0.92 and substantially reduces mean squared error by approximately 50% and 70%, respectively. The results show that the framework provides an accurate and computationally efficient foundation for constraint-aware, data-driven mix proportioning.

High-performance concrete (HPC) is an advanced construction material valued for its superior strength and durability. Unlike conventional concrete, which primarily consists of Portland cement, fine and coarse aggregates, and water, HPC incorporates supplementary cementitious materials (SCMs) such as fly ash and blast furnace slag, together with chemical admixtures such as superplasticizers [1,2]. These blended cement systems enhance workability, improve long-term performance, and reduce the environmental impact by lowering the dependence on Portland cement, which is a significant contributor to CO 2 emissions. As a result, HPC supports both structural efficiency and environmental sustainability in construction [1,3].

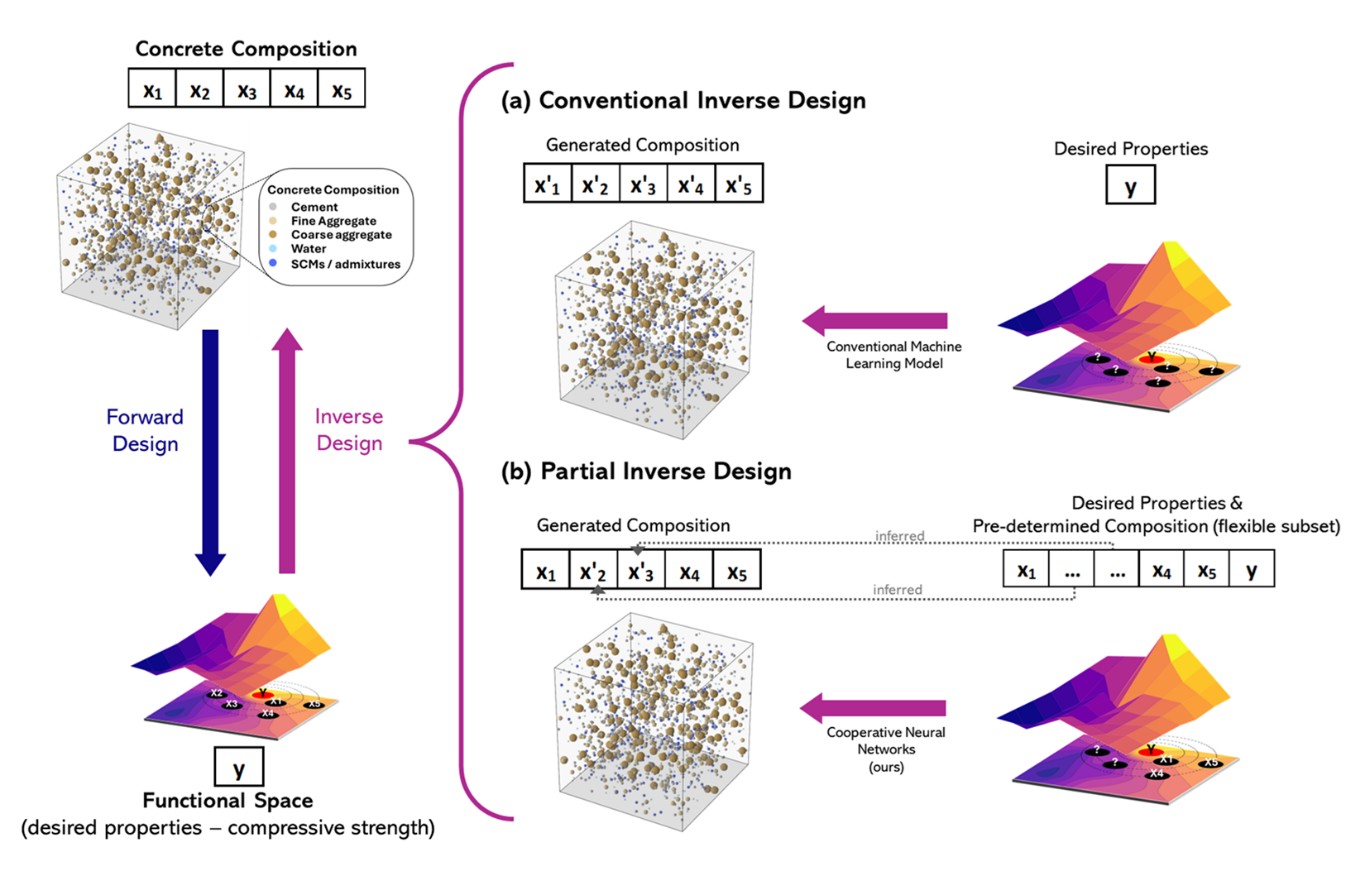

Alongside material innovations and the increasing availability of high-quality experimental data, the data-driven design (DDD) paradigm has emerged as a transformative approach in concrete research and materials science [4,5,6,7]. DDD is broadly defined as a methodology in which empirical or simulated data serve as the foundation for predictive or generative modeling to support engineering decision-making [8,9]. Unlike conventional approaches that rely heavily on explicit physical or mechanistic models, DDD employs predictive models that capture the complex and often nonlinear relationships directly from data. In doing so, it enables rapid property prediction, reduces the need for time-consuming experiments or costly simulations, and facilitates the intelligent exploration of complex design spaces. Within the data-driven design paradigm, design tasks can be categorized into distinct approaches. Forward design (as illustrated in Fig. 1) represents the predictive approach, in which known input variables (e.g., mix proportions) are used to estimate material properties such as compressive strength. This process involves developing a predictive or surrogate model that serves as an efficient substitute for complex and computationally expensive physical models [10,11]. The surrogate model learns from available data on design parameters and their corresponding performance metrics, enabling rapid and reliable evaluation of candidate mix design solutions. One of the early applications of machine learning-based surrogate modeling in the concrete domain was introduced by Yeh in 1998 [2], who developed an artificial neural network (ANN) model to predict compressive strength of HPC. The study concluded that ANN outperformed traditional regression models in accuracy and proved to be a convenient tool for analyzing the effects of mix proportion variables through numerical experiments. Following this methodology, Yeh in 2006 [12] also applied neural networks as surrogate models in combination with design of experiments to investigate the effects of fly ash replacement, curing age, and water-binder ratio on the compressive strength of both low-and high-strength concrete. Later on, with the rapid advancement of machine learning research, various algorithms were applied in the cement and concrete domain [13], including ANN [14,15,16,17,18], polynomial neural network hybrid models [4], support vector machine (SVM) and its hybrid model [16,18,19], Gaussian process (GP) model [1,20], decision tree-based model [20,21], ensemble model [5,15,16,18,20,21,22,23], and other combination or hybrid approaches [24,25]. Fazel Zarandi et al. in 2008 [4] constructed and evaluated six hybrid neural network frameworks integrating fuzzy logic with polynomial neural networks, aiming to identify the most effective model for predicting the compressive strength of concrete mix designs. Cheng et al. in 2012 [19] developed a hybrid model that integrated Fuzzy Logic (FL), weighted SVM, and fast messy genetic algorithm (fmGA) into an adaptive system called Evolutionary Fuzzy Support Vector Machine Inference Model for Time Series Data (EFSIMT), demonstrating its effectiveness in predicting the compressive strength of concrete. Ke and Duan in 2021 [1] employed GP models as surrogate models in their inverse design architecture to predict concrete compressive strength, highlighting their ease of integration with Bayesian inference methods. More recently, the application of surrogate models to predict compressive strength in advanced concretes has been demonstrated by several studies. Wijesundara et al. in 2025 [5] evaluated seven predictive models, including SVM, ensemble tree models, and multi-layer perceptron (MLP), for ultra-high-performance fiber-reinforced concrete (UHPFRC). M. Ishana et al. in 2025 [25] developed a hybrid model that combines ANN with a genetic algorithm (GA), referred to as ANN-GA, for HPC.

In contrast, inverse design represents a target-driven paradigm that reverses the usual direction of prediction. Rather than estimating material properties from known mix compositions, it determines the combination of design variables required to achieve a specified target property, such as compressive strength (Fig. 1). Conceptually

This content is AI-processed based on open access ArXiv data.