Smart manufacturing can significantly improve efficiency and reduce energy consumption, yet the energy demands of AI models may offset these gains. This study utilizes in-situ sensing-based prediction of geometric quality in smart machining to compare the energy consumption, accuracy, and speed of common AI models. HyperDimensional Computing (HDC) is introduced as an alternative, achieving accuracy comparable to conventional models while drastically reducing energy consumption, 200$\times$ for training and 175 to 1000$\times$ for inference. Furthermore, HDC reduces training times by 200$\times$ and inference times by 300 to 600$\times$, showcasing its potential for energy-efficient smart manufacturing.

Smart manufacturing has shown the potential to reduce energy consumption and enhance sustainability by increasing material and operational efficiency [1,2]. A critical enabler of these benefits is the integration of in-situ sensing and analysis, which provides real-time insights into manufacturing processes to allow data-driven adjustments. This capability complements three key aspects of smart manufacturing where Artificial Intelligence (AI) plays a key role, i.e., modeling and optimization under limited mechanistic knowledge [3,4], process and equipment analysis and monitoring [5], and real-time process and system control [6,7,8,9,10]. The as-yet limited adoption of smart manufacturing by small and medium enterprises, which comprise ≈ 75% of US manufacturing, indicates tremendous growth potential.

Research in computer science and sustainability indicates that training and inference of AI models needs significant energy [11,12]. Thus, the sustainability advantage of smart manufacturing could be negated by energy-hungry training and inference of the requisite AI models. Optimization of computational workloads only reduces training costs by 10s of percentage points, often at the cost of reduced training/inference speed or prediction accuracy [13,14]. This is problematic for smart manufacturing, e.g., rapid and repeated inference is critical for real-time control and offline optimization. The cumulative energy usage of repeated inference can overwhelm that of training, which is significantly less frequent [15]. At the same time, speedy training is critical when adapting pre-trained AI models to unseen scenarios (e.g., new materials or part geometries).

In this context, in-situ sensing presents an opportunity in smart manufacturing to reduce computational energy demands by providing real-time data that enables more efficient AI pipelines. The integration of sensing technologies provides the ability to mitigate energy usage without compromising prediction accuracy or training and inference speeds. Therefore, there is a need to quantify the energy usage of AI models in smart manufacturing, more specifically in scenarios that emphasize in situ sensing and analysis, to realize sustainable and efficient manufacturing operations.

This paper presents our early, but promising, work towards addressing this need. In-situ monitoring of geometric deviation in 5-axis Computer Numerical Control (CNC) machining is used as an example testbed. Multiple real-time acquired sensor signals from the CNC are fed to an AI model that classifies geometric deviation of relevant features as low, average or high. Several popular AI models and the rarely explored HyperDimensional Computing (HDC) approach are examined. In addition to comparing accuracy and training/inference speed a key novelty lies in comparison of the energy needed for training and inference. The future impact on balancing pervasiveness of AI-driven smart manufacturing with sustainability is discussed.

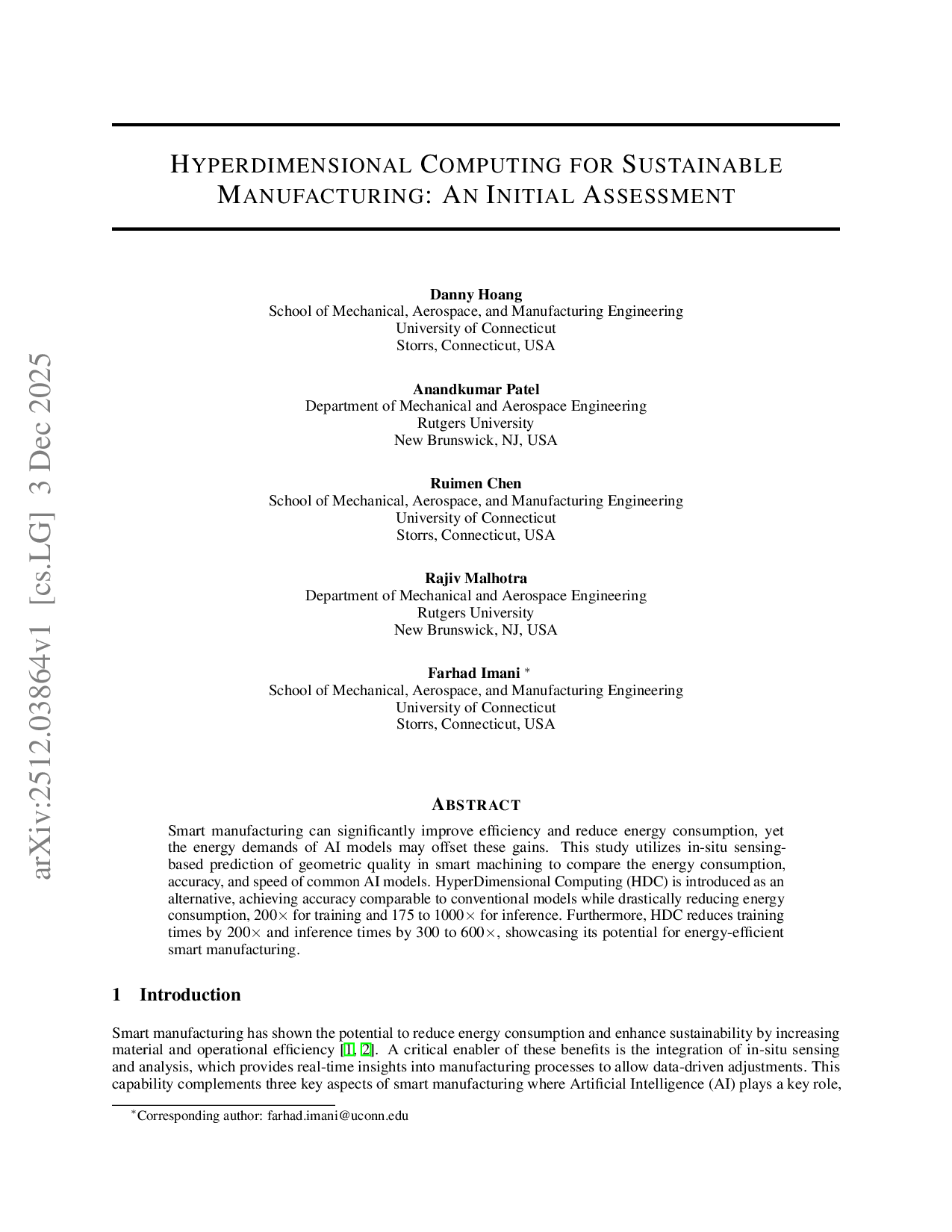

Figure 1 shows a schematic of the methodology. It consists of three elements, i.e., experiments and data generation, AI modeling and comparison of different leaning methods.

Training and testing data were experimentally generated using a LASERTEC 65 DED hybrid CNC DMG machine to fabricate the complex part depicted in Fig. 1a. A total of 18 such parts were machined using 1040 Steel feedstock and same machine settings. Worn bits were replaced based on expert experience. During fabrication, signals from the CNC were recorded at a frequency of 500 Hz using a Siemens Simatic IPC227E device. The toolpaths were created using Siemens NX. Two features were selected for analysis, i.e., a 25.4 mm left counterbore diameter and a 2.54 mm radius, as highlighted in red in Fig. 1a. The counterbore was created using an end mill bit, and the radius was generated using a corner radius tool.

The real-time measured signals consisted of load (L), current (C), torque (T), command speed (CS), control differential I (CD I), control differential II (CD II), power (P), contour deviation (ConD), axis position (AX), encoder position I (EP I), encoder position II (EP II), velocity feed forward (VFF), and torque feed forward (TFF). The signals CD I, CD II, EP I, and EP II are proprietary to the machine. Each signal was recorded on either five channels (axes only) or six channels (axes plus spindle), across the five axes and the spindle, resulting in a total of 64 channels. Sampling was performed specifically on the recorded channels to ensure sufficient data for training purposes. The sampling involves non-overlapping n-gram windows that capture specific time intervals in the time series data. These windows are concatenated to create a single feature vector sample, increasing the number of data samples while preserving the temporal relationship. Each class was balanced. A GOM ATOS ScanBox was used to measure the geometry of each machined feature and compared it to the ideal geometry. Z-scores were

This content is AI-processed based on open access ArXiv data.