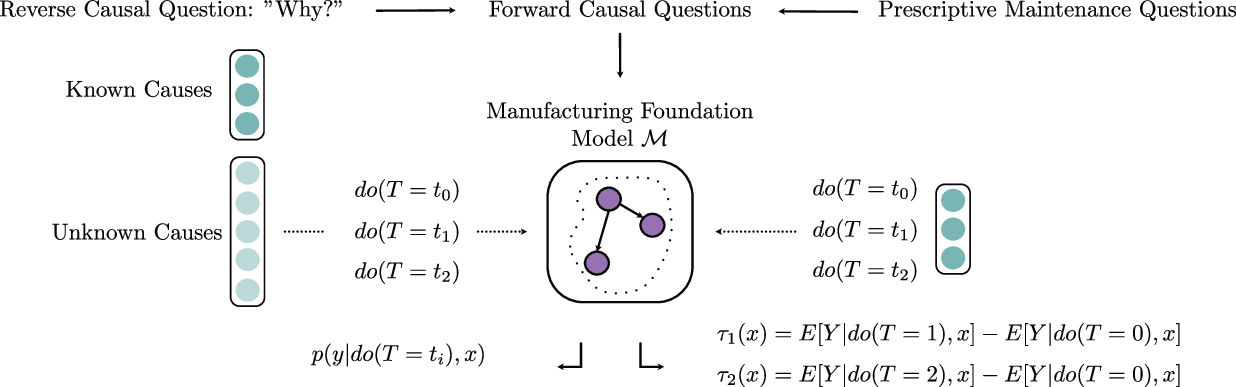

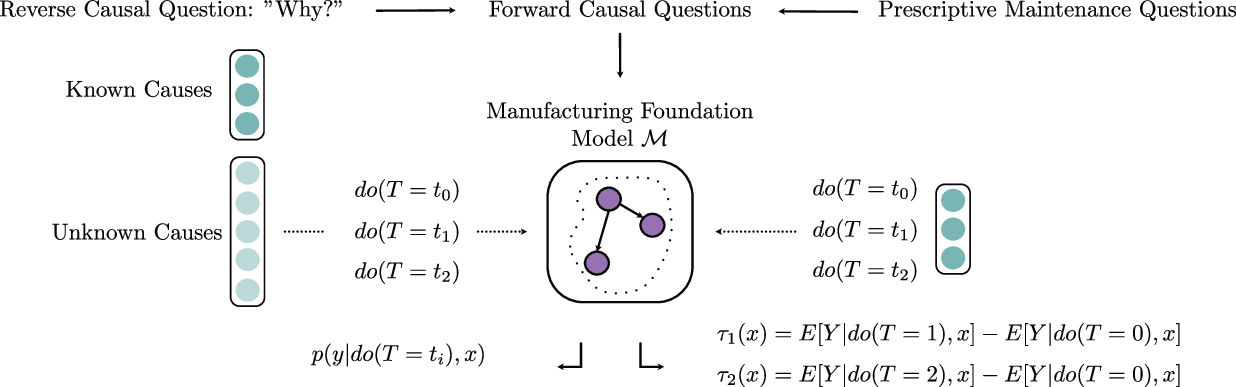

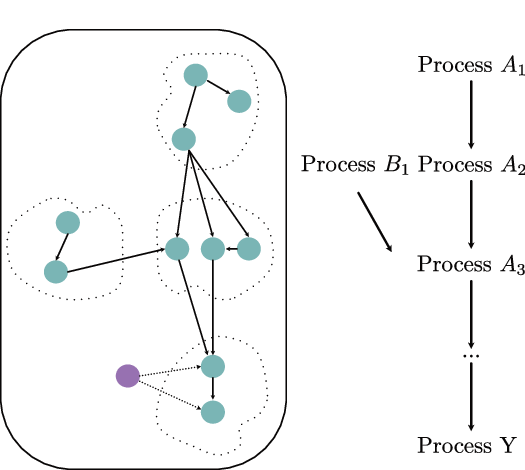

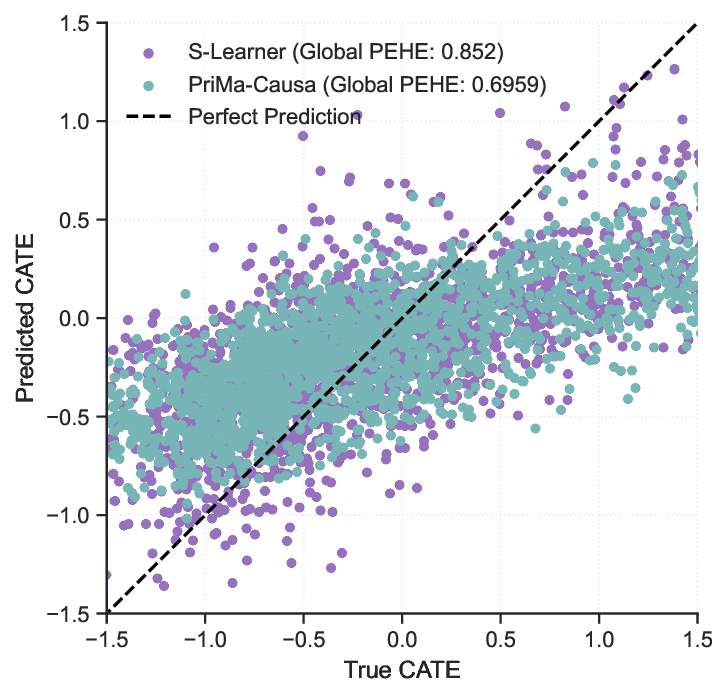

The transition to prescriptive maintenance in manufacturing is critically constrained by a dependence on predictive models. These models tend to rely on spurious correlations rather than identifying the true causal drivers of failures, often leading to costly misdiagnoses and ineffective interventions. This fundamental limitation results in a key-challenge: while we can predict that a failure may occur, we lack a systematic method to understand why a failure occurs, thereby providing the basis for identifying the most effective intervention. This paper proposes a model based on causal machine learning to bridge this gap. Our objective is to move beyond diagnosis to active prescription by simulating and evaluating potential fixes toward optimizing KPIs such as Overall Equipment Effectiveness (OEE). For this purpose a pre-trained causal foundation model is used as a "what-if" model to estimate the effects of potential fixes. By measuring the causal effect of each intervention on system-level KPIs, it provides a data-driven ranking of actions to recommend at the production line. This process not only identifies root causes but also quantifies their operational impact. The model is evaluated using semi-synthetic manufacturing data and compared with a baseline machine learning model. This paper sets the technical basis for a robust prescriptive maintenance framework, allowing engineers to test potential solutions in a causal environment to make more effective operational decisions and reduce costly downtimes.

Prescriptive analytics (PA) is considered the most complex and sophisticated form of business analytics. Its primary purpose is to identify the best course of action for achieving a specific desired outcome Wissuchek and Zschech [2025]. Unlike descriptive or predictive models, which focus on summarising the past or predicting the future, PA aims to answer the crucial question: "What needs to be done/should be done, and what do I need to do to achieve this?" Wissuchek and Zschech [2025]. The core objective is to generate actionable decisions Ansari et al. [2019] that support or automate complex decision-making processes. Wissuchek and Zschech Wissuchek and Zschech [2025] divide this decision-making process into three phases. In phase 1, evaluation of alternatives, problems are identified and alternative courses of action are generated and evaluated. In phase 2, the most suitable alternative is selected and executed, and phase 3 involves evaluating the effectiveness and results of the decision made. The extensive digitalisation of industrial processes, frequently linked to smart manufacturing and cyber-physical production systems, has generated significant research interest in data-driven decision-making processes, particularly in the context of maintenance planning as applied in prescriptive maintenance Wissuchek and Zschech [2025], Orošnjak, M.; Saretzky, F.;Kedziora, S. [2025]. The objective in this context is to provide actionable recommendations for decision-making in order to optimise future maintenance processes and minimise the probability of failures Ansari et al. [2019], Nemeth et al. [(2018]. The development of prescriptive maintenance models requires the systematic combination of information from the three fundamental stages of knowledge-based maintenance -descriptive, diagnostic and predictive analytics Ansari et al. [2019]. Decision recommendations are generated from derived combination rules Ansari et al. [2019] or predictions based on identified failure patterns Nemeth et al. [(2018]. These prediction models themselves are based on statistical correlations and patterns present in the training data. To derive recommendations for action and decision-making, predictive models are supported by the use of explainable artificial intelligence Madathil et al. [2025]. For this purpose, post-hoc explanations Belmouadden et al. [2025] and intrinsic models are used to find critical features or perform root cause analysis Muaz et al. [2025], the results of such analyses being used to support decision-making. The application of these methods can lead to reliance on models whose reliability is compromised by the learning of arbitrary or spurious correlations Carloni et al. [2025]. Therefore, predictions from machine and deep learning models alone are often insufficient for data-driven decisions, as a comprehensive understanding of the consequences of an intervention is required Abécassis et al. [2025]. In order to minimise the occurrence of costly misdiagnoses and ineffective technical interventions, it is essential to determine the underlying cause of an event as well as quantify the interventional effect. Causal inference is a foundational methodology focused on distinguishing true cause-effect relationships from mere statistical associations, essential for robust decision-making and predicting the effects of deliberate interventions Carloni et al. [2025], Abécassis et al. [2025], Pearl [2009]. Causal AI specifically aims to equip machines with the ability to discern these causal relations by modelling underlying data-generating processes Hennebold et al. [2025] to reason across the distinct layers of the causal hierarchy: association, intervention, and counterfactual reasoning Pearl [2009].

Consequently, a gap exists as current prescriptive maintenance methods, rooted in associational logic, are often insufficient for quantifying the causal consequences of an intervention, a challenge this paper addresses: (1) We integrate causal machine learning into the prescriptive maintenance framework in the form of a technical basis. (2) We construct a data generation prior that has been adapted to a manufacturing environment. (3) Our trained foundation model PriMa-Causa for estimating conditional average treatment effects is evaluated using semi-synthetic data sets.

In section 2, we present the decision-making process in prescriptive maintenance, its problems and solutions through causal machine learning. Section 3 presents an automatable technical basis for prescriptive maintenance recommendations and the model architecture. In section 4, we evaluate our model on semi-synthetic manufacturing data. Finally, section 5 summarises the main results and outlines future perspectives.

In phase one of the three-phase decision-making process, according to Wissuchek and Zschech [2025], an adaptive prescriptive analysis system (PAS) identifies problems, generates alternative recommendations for action and classifies them.

This content is AI-processed based on open access ArXiv data.