Process Integrated Computer Vision for Real-Time Failure Prediction in Steel Rolling Mill

📝 Original Info

- Title: Process Integrated Computer Vision for Real-Time Failure Prediction in Steel Rolling Mill

- ArXiv ID: 2510.26684

- Date: 2025-10-30

- Authors: Researchers from original ArXiv paper

📝 Abstract

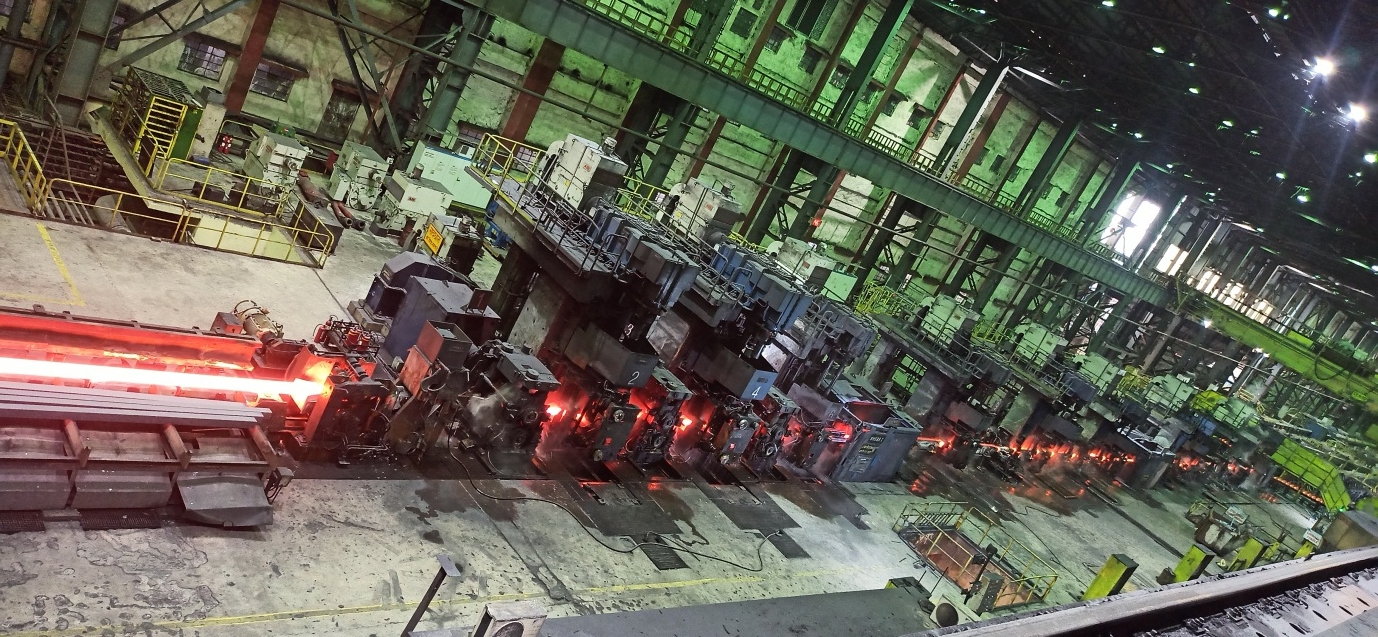

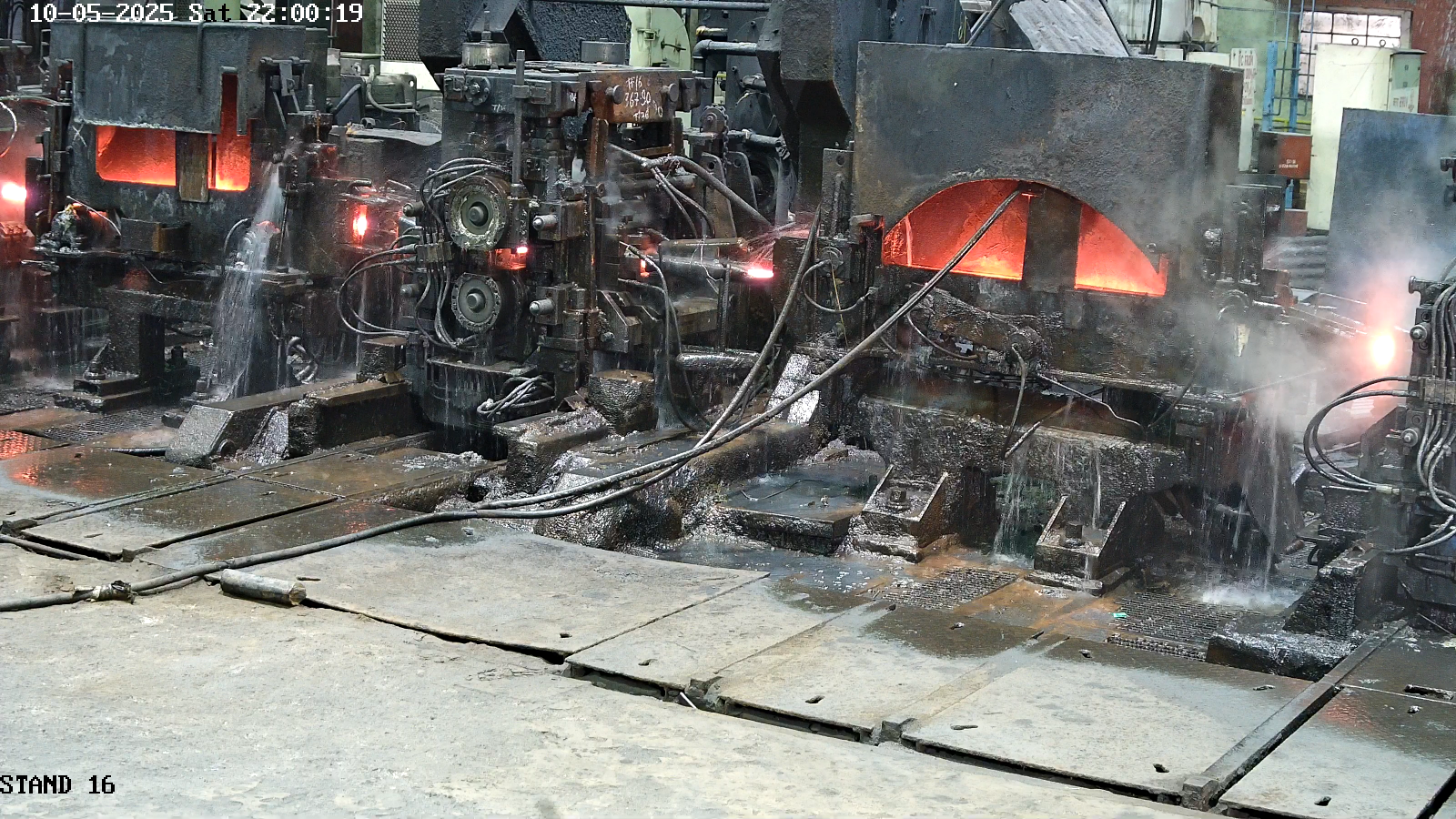

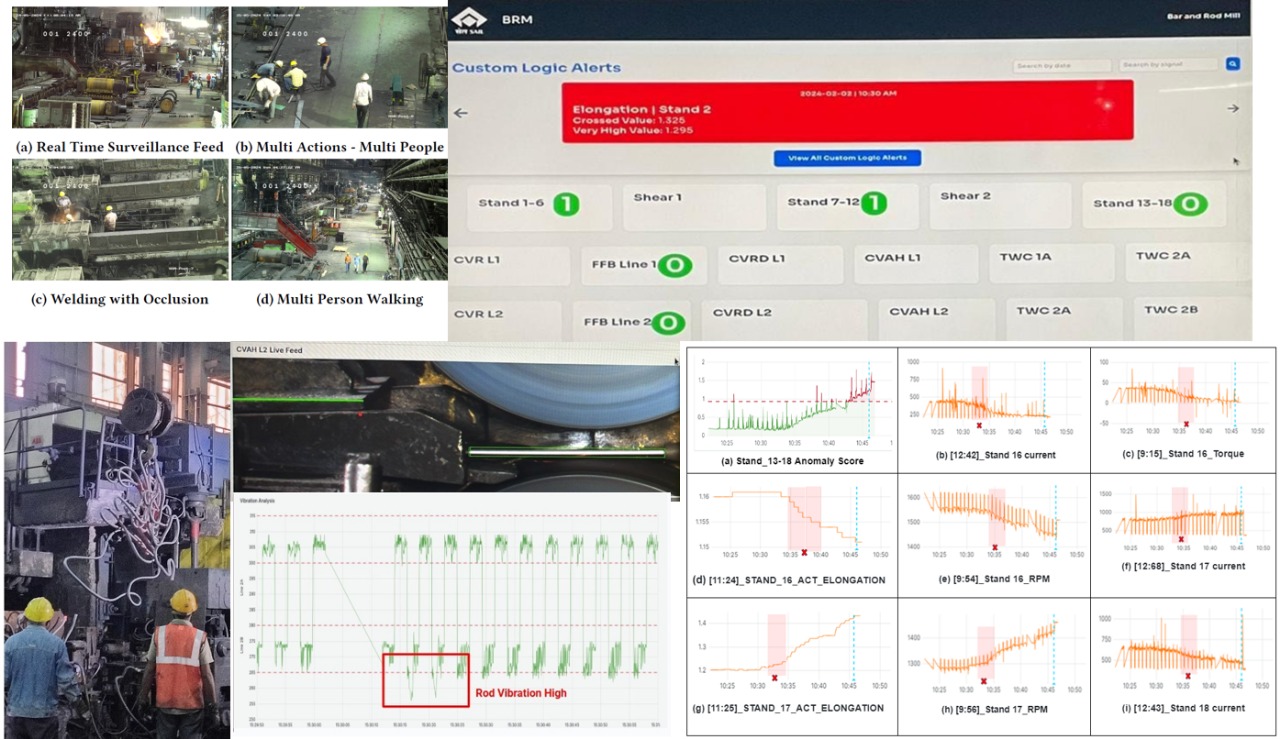

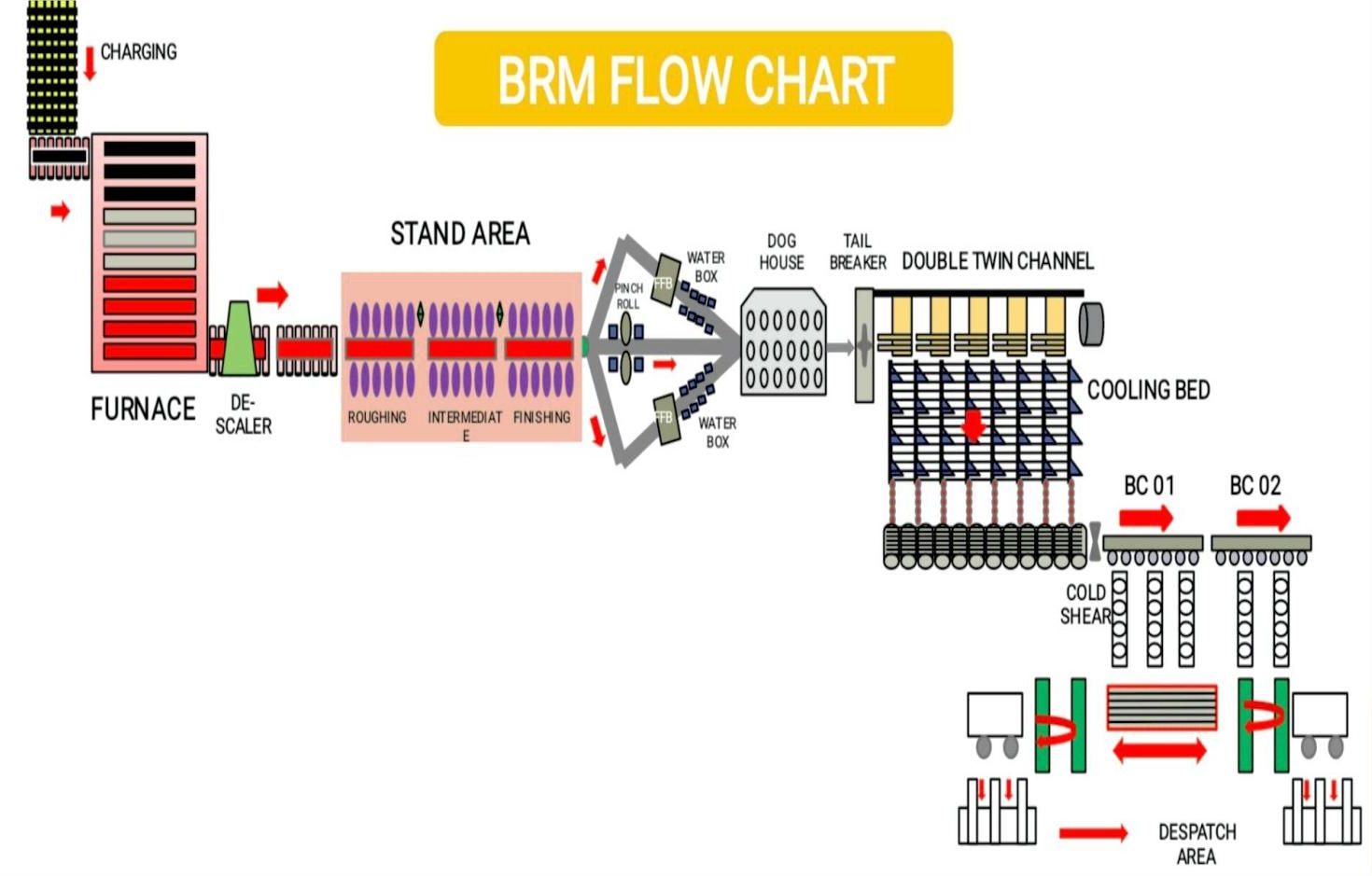

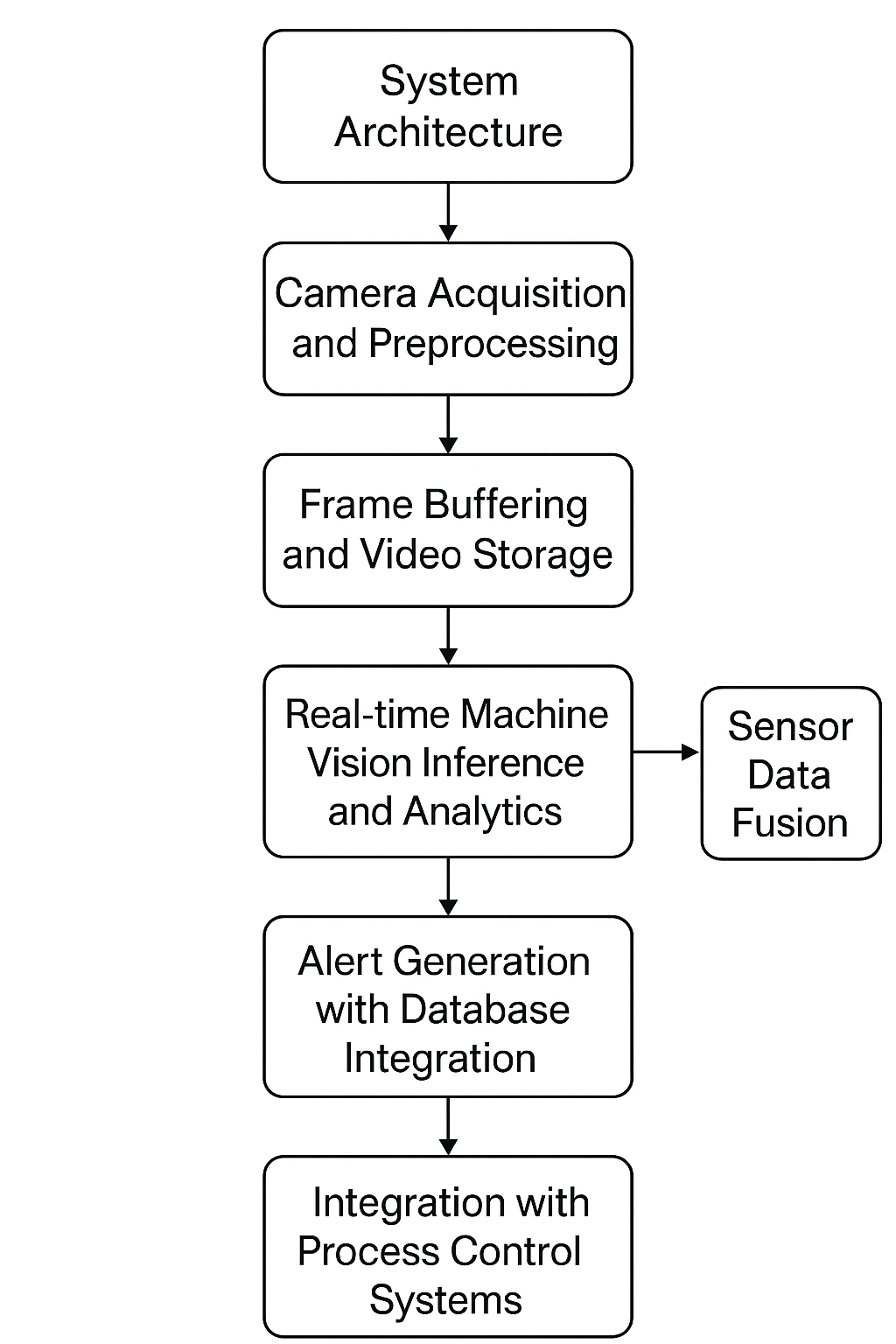

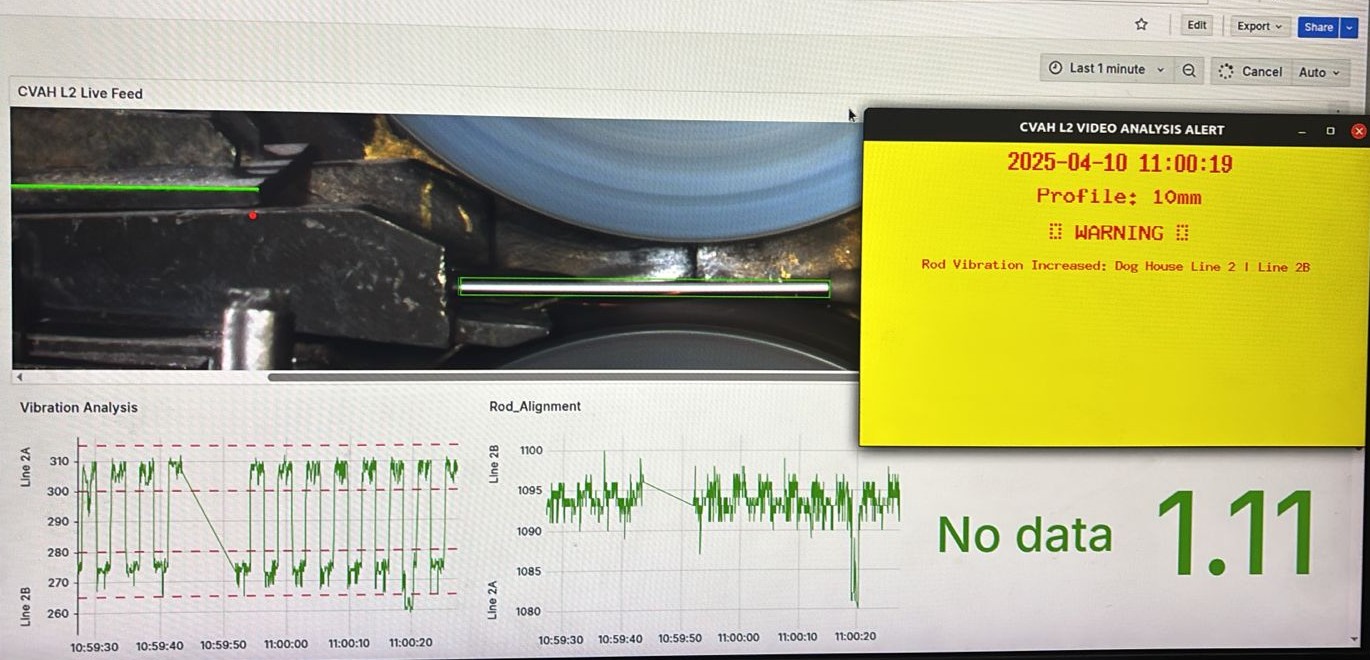

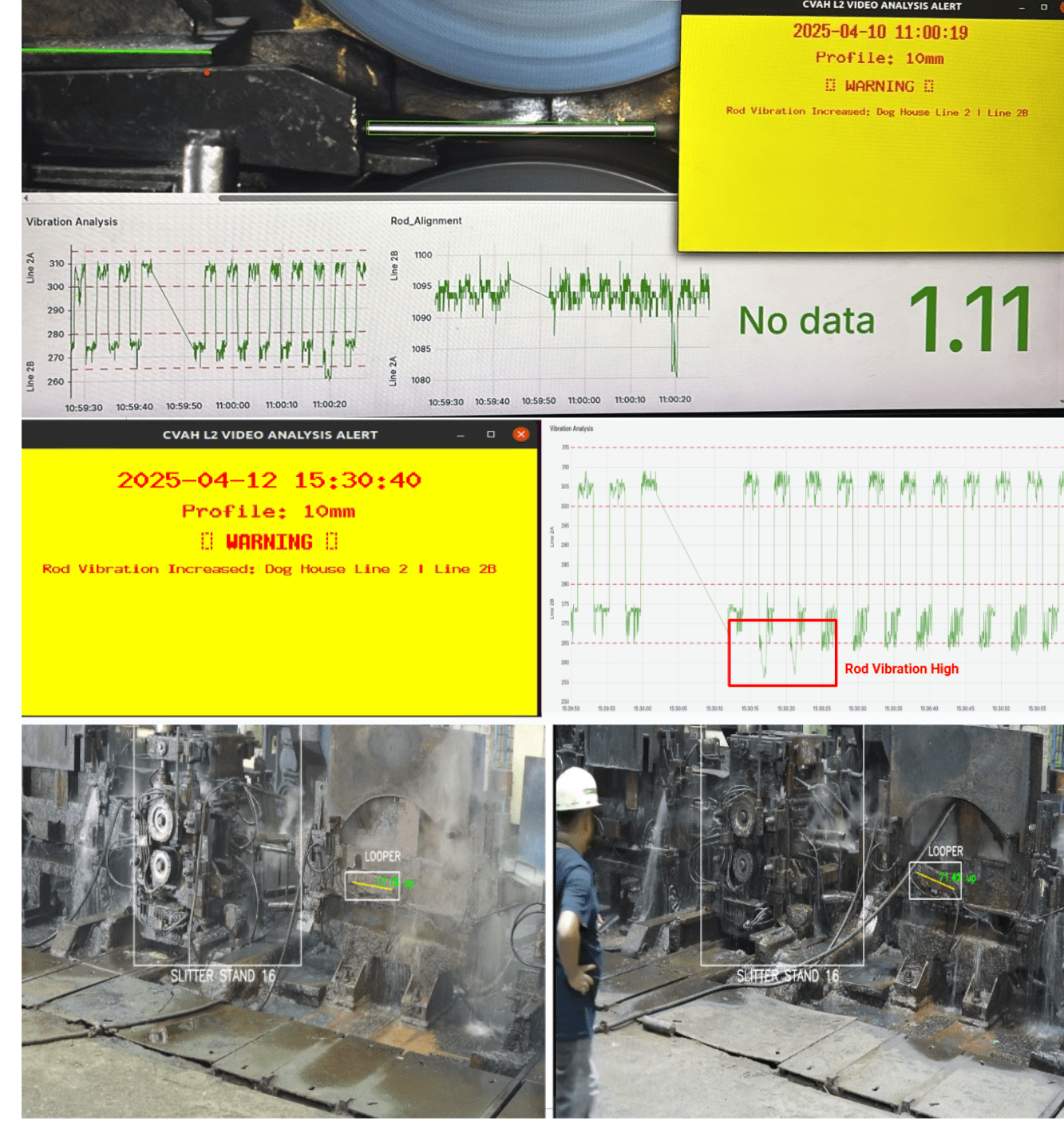

We present a long-term deployment study of a machine vision-based anomaly detection system for failure prediction in a steel rolling mill. The system integrates industrial cameras to monitor equipment operation, alignment, and hot bar motion in real time along the process line. Live video streams are processed on a centralized video server using deep learning models, enabling early prediction of equipment failures and process interruptions, thereby reducing unplanned breakdown costs. Server-based inference minimizes the computational load on industrial process control systems (PLCs), supporting scalable deployment across production lines with minimal additional resources. By jointly analyzing sensor data from data acquisition systems and visual inputs, the system identifies the location and probable root causes of failures, providing actionable insights for proactive maintenance. This integrated approach enhances operational reliability, productivity, and profitability in industrial manufacturing environments.💡 Deep Analysis

Deep Dive into Process Integrated Computer Vision for Real-Time Failure Prediction in Steel Rolling Mill.We present a long-term deployment study of a machine vision-based anomaly detection system for failure prediction in a steel rolling mill. The system integrates industrial cameras to monitor equipment operation, alignment, and hot bar motion in real time along the process line. Live video streams are processed on a centralized video server using deep learning models, enabling early prediction of equipment failures and process interruptions, thereby reducing unplanned breakdown costs. Server-based inference minimizes the computational load on industrial process control systems (PLCs), supporting scalable deployment across production lines with minimal additional resources. By jointly analyzing sensor data from data acquisition systems and visual inputs, the system identifies the location and probable root causes of failures, providing actionable insights for proactive maintenance. This integrated approach enhances operational reliability, productivity, and profitability in industrial ma

📄 Full Content

📸 Image Gallery