Gas turbine diagnostic system

📝 Original Info

- Title: Gas turbine diagnostic system

- ArXiv ID: 1111.0233

- Date: 2011-12-13

- Authors: Shuvatov Talgat and Suleimenov Batrbek

📝 Abstract

The creation of the systems models is very actual at present time, because it allow to simulate the work of some complex equipment without any additional spends. The given model of gas turbine is allowed to test and optimize the software for gas turbine automation systems, study station personal, like operators and engineers and will be useful for diagnostics and prediction tasks to analyze the efficiency of the gas turbine.💡 Deep Analysis

📄 Full Content

Gas turbine diagnostic system Shuvatov T.T. Suleimeno B.A.

Abstract. The creation of the systems models is very actual at present time, because it allow to simulate the work of some complex equipment without any additional spends. The given model of gas turbine is allowed to test and optimize the software for gas turbine automation systems, study station personal, like operators and engineers and will be useful for diagnostics and prediction tasks to analyze the efficiency of the gas turbine.

This software system is designed for simulation and control of the gas turbine

units, to protect and perform simulation of automatic control functions of the Gas

Turbine Compressor Unit and of the Compressor Station’s stationary equipment, to

adjust and stabilize the process variables in different operating modes of the GTCU.

The main functions of the system is:

Mathematical Modeling.

During the process of building a mathematical model of the technological

process all possible process variables are taken into consideration, because the

adequacy of the model to its real object is an important critical factor in the successful

solving of diagnostic and optimization tasks. The mathematical model of the

technological process reflects its main functionality and dependency between the most

essential characteristics of the process and its key parameters and entrance conditions.

Forecasting.

On the basis of the simulation model the system creates the optimal schedule

of functioning of the equipment according to a production plan.

Personnel Training.

This software simulation model can be used to familiarize the compressor

station personnel with the main principles of operation of the microprocessor based

ACS GTCU, and also can be used to train CS’ operational personnel to work with this

type of ACS. The system represents the modular software environment, where can be

simulated the model of the GTCU to perform the main functions of ACS in the real-

time (to run and control Turbine, to load GTCU in the mode “Ring” or “Trunk line”),

and also control the auxiliary equipment (pumps, fans, etc.)

Software Testing

By carrying out the test procedure on the simulation software the ACS GTCU

control program can be debugged rapidly. In the first place, the performance of the

control algorithm of the GTCU, for both the main and the auxiliary equipment, is

verified. Moreover, all functionality of the SCADA system can be tested.

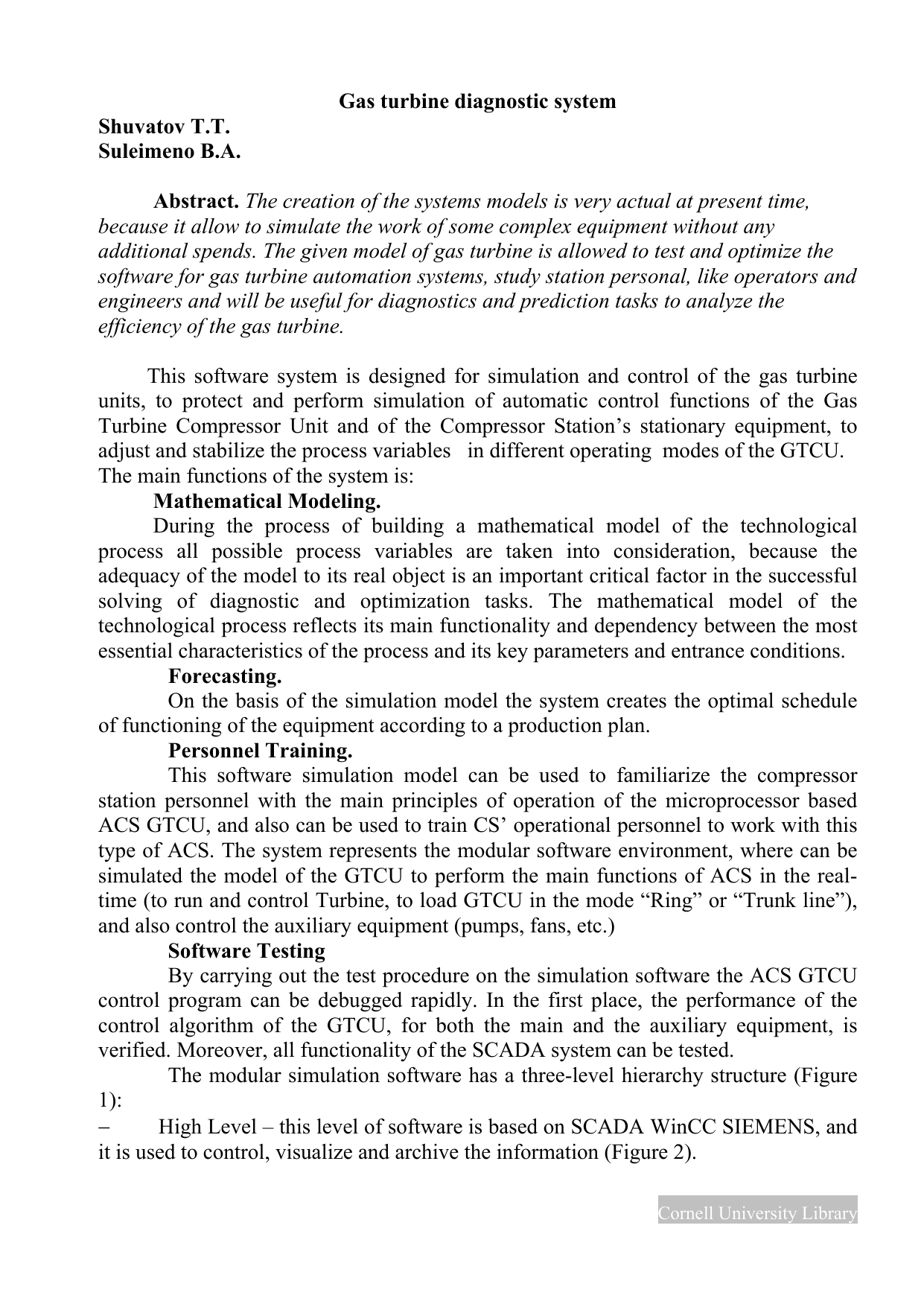

The modular simulation software has a three-level hierarchy structure (Figure

1):

−

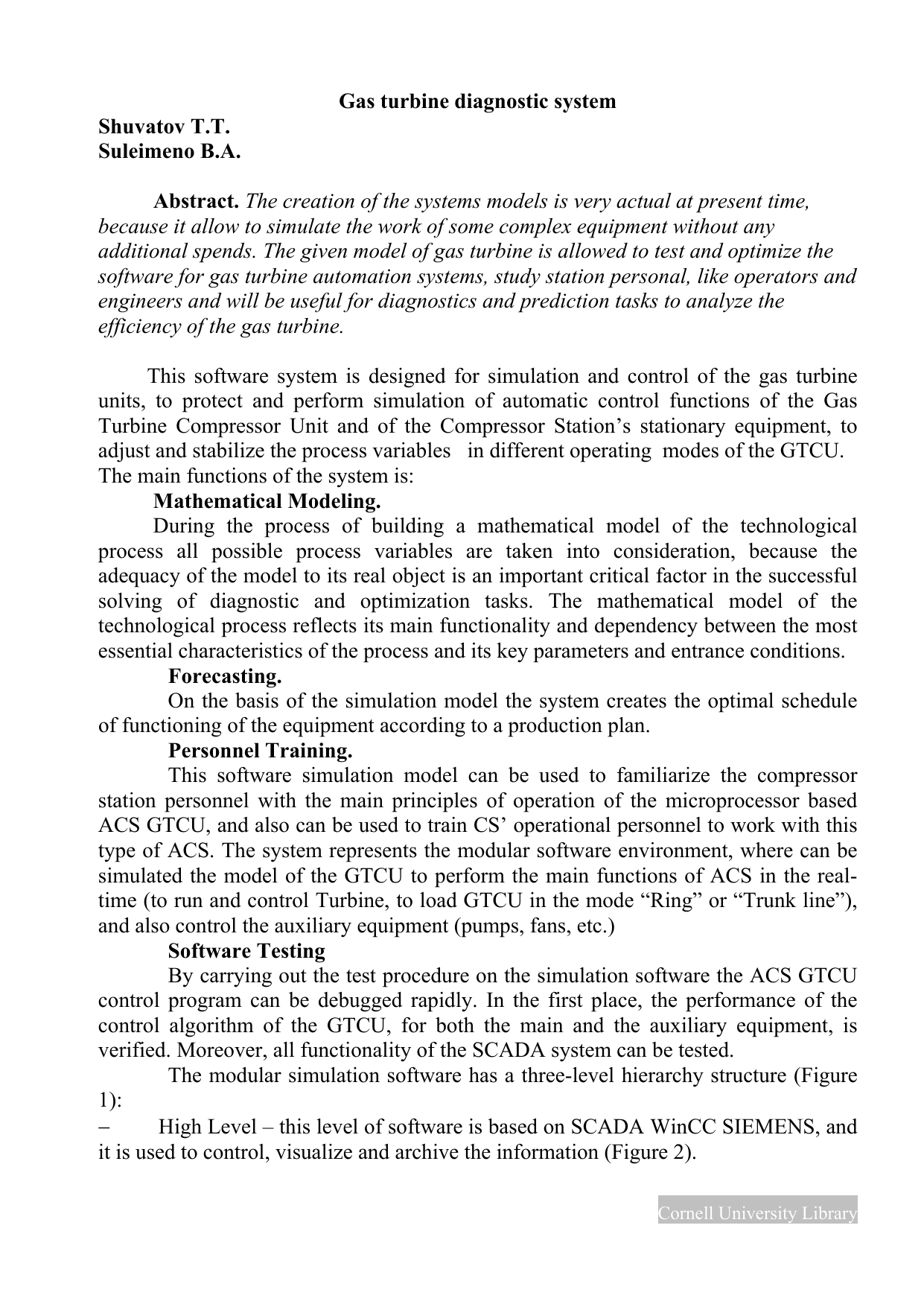

High Level – this level of software is based on SCADA WinCC SIEMENS, and

it is used to control, visualize and archive the information (Figure 2).

Cornell University Library

−

Middle Level - this level of software is based on PLC TRICONEX 3000

Trident V9, and was developed in the TriStation 1131 programming environment (to

run the simulation model, the TriStation 1131 should operate in the emulation mode)

−

Lower Level – this level of the software is based on the VISSIM simulation

environment, and this software simulates all operating modes of the GTCU and field

equipment (sensors, measurement instrumentation).

DDE (Dynamic Data Exchange) protocol is used to transmit the data between the

levels.

Figure 1 – The Structure of the simulation model of the GTCU

As mentioned above, the Lower Level of the simulation model is based on

VISSIM (Visual Simulation) software, version 5.0, and this software package is fully

used to simulate the GTCU in run mode, including all functionality of the main and

auxiliary units.

At the Lower Level of the software model the following devices are simulated:

−

pressure and temperature sensors;

−

the main and auxiliary Lube and Seal oil pumps, and emergency Lube oil

pumps;

−

the liquid cooling supply system fans, roof fans.

The datas used in this simulation model were analyzed and gathered from real

working Gas-Turbine Units GTK 10i, the Turbines located in the compressor station

“Chizha”(Uralsk). The dependences between the different parameters of Turbine were

determined and then the transfer functions were identified which allows us to get the

exact simulation model of the GTCU.

Cornell University Library

Figure 2 Pictures of SCADA system

Figure 3 – The VISSIM Simulation Model of GTCU based on GTK -10i TMC run mode

Cornell University Library

The construction of mathematical model based on measurement of inputs and output signals is a approximation of functional dependence. In our case we have to build the model of gas turbine. To create the adequate model it is necessary to take care about the functionality of the main parts of gas turbine and define the cause-and- effect connection between them. In that case we have to use identification tools to find the functions between input and output parameter

📸 Image Gallery